The Loftus family is in the process of inventorying and cataloging the artifacts that will be on display in the mobile museum. You are always welcome to stop by our office at 633 N. Third Ave. Stayton, Oregon and get a mini tour in a 1898 Queen Anne Victorian and enjoy a cup of coffee in the cafe

ORAL HISTORY TRANSCRIPT

JOSEPH P. LOFTUS INTERVIEWED BY DOYLE MCDONALD

JULY 1997

[This oral history with Joseph P. Loftus was conducted by Doyle McDonald for the Johnson Space Center Oral History Project.]

LOFTUS: How do you want to begin?

MCDONALD: I'd really like to start with people that might possibly be at risk for being older, might be missing before we can get to them, that had important parts of the program, maybe well known to you or well known inside the industry, but are not well known for historical purposes.

LOFTUS: There are a fair number of people in the area who have been with the program since the beginning. Bob [Robert F.] Thompson, who, in Mercury, ran the recovery division, later was the program manager for Skylab, and then was the program manager for shuttle, has sort of a unique perspective on having seen all these things go on.

Another fellow around who is up in the Woodlands teaching is Bob [Robert O.] Piland. Bob played a number of different roles throughout things. He was, at one time, the Apollo Program manager and [then] took on all the development of experiments for the lunar missions. He developed our Earth Resources Program and ran that rather effectively for a long time. He's teaching now. He has a lot of good perspectives. When he became the Apollo Program manager, he got us all out into what is now, or was the auditorium at Ellington [Field, Houston, Texas] before it was torn down, and sort of said, "I don't want to hear about problems. In a program this size, if you can't find a problem, you are really incompetent." [Laughter] That gives you a little flavor on him.

There are a couple of people here. Brian Erb, who is the Canadian Space Agency representative over in the International Space Station office, was one of the fellows that we picked up when the Canadian Government decided to go out of the war-plane business. Canada at that time had in development an AVRO aircraft, the 105, which was the hottest airplane in the world, really a super bird. And the Canadian Government decided they couldn't compete with the U.S. and Europe, so they said, "Don't drive another rivet. Get cutting torches. Get rid of it."

So we and McDonnell and, at that time, North American went up to Canada and hired all those guys. [Laughter] Because we needed good engineers. So there was a large contingent of Brits and Canadians and what have you who worked in Mercury and on through Apollo that came about through that policy decision of the Canadian Government.

MCDONALD: Is that where John [D.] Hodge came from?

LOFTUS: Yes, amongst others. One of the people who had a lot of influence early in Mercury and on through Apollo was Bob [Robert G.] Chilton. Bob was a guidance navigation type and headed our Guidance and Navigation Division for many years…[and] he was also the one who, starting in Mercury and on through Apollo, established the interfaces that we used with the Draper Labs at MIT [Massachusetts Institute of Technology] for all of our work. So he has some fairly unique perspectives on things.

MCDONALD: Is he still in this area?

LOFTUS: Yes. Last time I saw Bob was when they had the big Russian exhibit up in Dallas. We were both up there looking at it.

Another fellow who's been with the program and has some fairly unique perspectives is Tom [Thomas U.] McElmurry. Tom lives over here in Nassau Bay. He just retired for the third time from teaching up at Texas A&M. Tom was an instructor at the Air Force Test Pilot School out at Edwards and came here originally with Deke [Donald K.] Slayton, but then he worked a lot of the issues in Skylab for Thompson before he retired from government, having previously retired from the Air Force. So he's had an interesting perspective on a lot of these things, both from outside and inside.

Max [Maxime A.] Faget is still in the area. He, of course, was very fundamental in a lot of our engineering choices [and] was the Director of engineering. Another fellow in the area who had a lot of do with some of our early decisions in both Mercury and Apollo is Caldwell [C.] Johnson, who is also still in the area. One of the people who has a perspective on the early years of the flight medicine thing is [A.] Duane Catterson, C-A-T-T-E-R-S-O-N. He's in the area, and he's at Kelsey- [Seabold]. Last time I talked to him he was running their clinic out at Intercontinental.

MCDONALD: He was in flight medicine all the time he was here.

LOFTUS: One of the people who's got an interesting perspective is Jim McBarron. Jim has been in the suit business from the beginning, and Jim is still here and active in suits and EVA, and he's got sort of an interesting approach because he's also worked closely with Ingmar Skuog and Guy Severin, who are the guys who do European and Russian suits.

MCDONALD: There still a suit business here?

LOFTUS: Yes. Another fellow in the area who's retired but active in many ways is Reginald Machel. Reg worked Gemini, the original EVAs, crew interfaces and what have you, and then moved on to Skylab to do the same kind of things, and he retired early in the Shuttle Program.

One of the names I had put down was Gene Shoemaker, because Gene had worked with us in terms of teaching astronauts how to look out the window and recognize interesting geological phenomena, but Gene was killed last week in an automobile accident in Australia.

Richard [S.] Johnston is around. He lives over in Green Tee [Pearland]. He was one of the guys who we picked up from the Navy early in the program, and he ran our crew and Thermal Systems Division for its first fifteen years or so, and then he went on into a number of special assignments, like putting together a quarantine facilities when we brought stuff back from the moon and what have you. So he's had some interesting perspectives on the program.

Staffing was a problem early in the program, and one of the interesting things that happened is, the Air Force said to NASA, "Here's a roster of 6,000 ROTC graduates this year, and any of them you hire, we'll waive their service requirements." So we picked up about 600 fresh-outs, courtesy of the Air Force. Then there are others like myself who were on active duty who were detailed to NASA.

MCDONALD: When did you come [to NASA]?

LOFTUS: Well, I was on the original Mercury Selection Testing Group, and it turned out that a couple of the people, Charlie [Charles J.] Donlan, in particular, who was the deputy director of Space Task Group, and I had gotten to know each other working on the X-15. So he asked if I could come with NASA, and I didn't want to move my family at the time. We were at Wright Field. So I cut a deal where I was still at Wright Field, but I'd go work wherever they wanted me. So I didn't transfer until the Space Task Group moved down here in '62. …I was one of the first people to arrive in Houston because I came direct from Wright Field in Dayton. At that time, our facilities here were what's now the post office at Gulf Gate, and we were renting space all over the southeast part of town. So I've been with it since the beginning. I flew with guys like Slayton and [Virgil I. “Gus”] Grissom and Ed [Edward H.] White [II] at Wright Field.

MCDONALD: What do you see as the difference between those programs, the Wright Field programs and going into the Space Task Group? Obviously programs have evolved gradually. What do you see as the key differences between those programs and these programs today?

LOFTUS: You're saying Mercury versus shuttle?

MCDONALD: Just the evolution as it went along.

LOFTUS: Well, novelty. Here we were, a bunch of guys, most of us out of the airplane business, who were trying to understand about the space business, and so one of the things that we would do is, in the evenings, we'd have seminars where one of us would teach the rest of us about some subject on which he was expert. I had done a lot of work in the Air Force in terms of various optical illusions and optical phenomena in high-altitude flight. One of the reasons it's hard to see things is that you get what's called "empty field myopia." If there's nothing to see five miles out, your focus comes back inside the canopy, so you don't see things that are out there, even though you could see them if somehow or other you could focus out there. You see this phenomenon in regular experience where you can look through the window, or if the window is dirty, you can look at the window [and not see what is beyond it, similarly]…with a screen door, things of that variety.

So I used to explain all of these various phenomena, and that was of some significance. …When it came time to go to Apollo, one of the significant things about the moon is that it's a retro-reflective surface. That means that if…a line from the point you're looking at to the sun is above you, it's like driving into the fog with high beams on; you don't see anything. That's why we had such a steep approach and why we had to land [further] to the west if we delayed a day, because the approach path had to be above the line to the sun at the landing site or you wouldn't be able to see anything.

Other guys would teach what are cryogens, what are hypergols? So everybody learned orbital mechanics and learned all of these kinds of different things. It was exciting in the sense that you were learning so many different things and people were enthusiastic about sharing their knowledge. So it was a pick-up team, and we were all young. There were no old men in the space business. [Laughter] At the time we landed on the moon, the average age was thirty-four.

MCDONALD: In the agency?

LOFTUS: No, in this organization, [the Johnson Space Center, then called the Manned Spacecraft Center].

MCDONALD: That certainly changed.

LOFTUS: Yes.

MCDONALD: Do you think that that's necessary? Has it become so big and so complex that you can't learn fast enough to be [unclear]?

LOFTUS: No. I think that nowadays we can hire youngsters who learned in school what we had to learn on the fly, and they're very bright and they're very good, but we've got a very different problem. I'm not sure, for example, that Rocketdyne could have built the SSME [Space Shuttle Main Engines] had they not built the J-2 and the F-1. You had to have come up that learning curve.

I don't think people realize how much better we do things [today]. We fly eight shuttle flights a year and handle the Mir Program and the space station development with less people than it took us to do two Apollo flights a year. Now, a lot of that is just taking advantage of the state of the art in data processing and what have you. We do thermal analyses on the shuttle which are far more complex than those we did on Apollo, and it would take us a year to do a mission on Apollo. They'll do a much more complex shuttle mission in a matter of a few days, but they've got big UNIX workstations and silicon graphics, what have you, to do it all, computational power and visual graphics engineering. So there's a tremendous increase in productivity that has gone on. And the shuttle is just a marvelous piece of equipment. It's probably the most complex thing we've ever built.

MCDONALD: How do you see the X-33 and X-38 and local fly-back booster, those kind of things? [Telephone interruption]

Do you really think so?

LOFTUS: Well, I guess I don't have a real clear picture of where you guys want to get to.

MCDONALD: Well, what we're trying to do is get the names of the people, and then there's a second piece of that, which is we're looking for topics which we can cover. You were covering several of those when you were discussing how the training was different, computing power. I think both of those are very useful for us because they're not as flashy as SSMEs and F-1s, but approaching the program from the angle that the learning curve is what enabled us to build the SSME will be very useful to us when we're talking to rocket designers, engine designers.

LOFTUS: Well, to continue, then, along that line, software was a big issue for us in Mercury and Gemini and Apollo, because machine capability was limited so we were essentially doing everything in machine language, and that not only was difficult to do, but it made change control very, very difficult as well.

So, out of that, Jack Garman [phonetic] and I started an effort to develop a higher-order language suitable for use in things, and it got labeled "the Houston aerospace language," which was obviously a takeoff on HAL, and HAL, obviously, is IBM minus one. [Laughter] But that's the higher-order language with which we did the shuttle software, and we probably could not have developed a quad redundant asynchronous software suite for the shuttle had we not had a higher order compiler like that. So that was an exceptionally successful effort.

We did some pretty spectacular things in the world of software at the time. For example, the question was, how are you going to do the simulator for Apollo, and how is it going to be animated if you couldn't get a flight computer and you couldn't get the flight software and what have you? So a fellow by the name of Jim Rainey [phonetic] developed an emulation of the MIT [Massachusetts Institue of Technology] software, and we were on the air before they were. I can remember long sessions with Dick [Richard E.] Battin, [J.] Hal Lanning, and the MIT guys about whether that was the right way to go, and we said, "We've got no choice. We've got to have something to train with," and it was an extremely successful effort. Much of what we built for the Apollo mission simulators is the core of what we use for some of the shuttle mission simulators. We bought the optic system that provides a lot of the out- of-the-window views, and it was a good enough system that you could actually do star sightings navigation fixes, just like you would on the way to the moon. So that was a big activity.

One of the things that's been sort of a learning experience for us is that when we started out in Mercury, there was no formal interface between the manned space flight program and science, but we were curious about some things, so we did some experiments, and, of course, the science community sort of said we shouldn't have a bunch of amateur engineers deciding what is and what is not proper science to do in flight. So we began to get into the whole protocol of establishing science groups and peer review and what have you to sort of get good science, if you will. That was sort of a pretty secondary activity through Mercury and Gemini, because those were primarily, (A), in Mercury, can man survive and function in flight, and then in Gemini the question is, can you do the kind of complex maneuvering that's required to do rendezvous. Because we were debating whether or not we should go Earth orbit rendezvous or lunar orbit rendezvous, and it was the success in Gemini that helped us decide to go lunar orbit rendezvous.

That was sort of a gut-wrenching decision, because John [C.] Houbolt at Langley [Research Center] had made that proposal, and we became the advocates for that here, and, of course, the guys who were advocates for Earth orbit rendezvous and space stations were at Marshall [Space Flight Center]. I can remember the day that we sort of had the final round of discussions, and after all-day presentations by JSC [Johnson Space Center] and by the Marshall guys on the pros and cons of the approaches, Wernher [von Braun] said, "We are going to go lunar orbit rendezvous. It's the only way to get there in time." That was sort of a classy act on his part.

MCDONALD: [Unclear] were talking to some people who suggested we talk to Eberhard Rees, and we found that he evidently is not [unclear] support that, and they suggested we talk to Ernst Stulinger instead. Do you have any other people that it would be useful to talk to about the [unclear]?

LOFTUS: Herman Koelle is at the Technical University of Berlin. He will be at the IAF [International Astronautical Federation] in Turin in October. Herman was part of that group. He retired and subsequently was accused of having run prison labor activities at Peenemunde, but he has a lot of insight as to sort of the mentality of that group that came [from Germany].

Another guy you could talk to who has a fair amount of insight into a lot of that is Henry [O.] Pohl, P-O-H-L. Henry was here, ran our Power and Propulsion Division, but he actually started out at Marshall in the Redstone Arsenal before Marshall was created, as the Army enlisted man.

Another guy who's got a lot of insight into some of those things is [Joseph G.] Guy Thibodaux, who lives over here in Nassau Bay. [Telephone interruption]

A fellow you could talk to about some of the Marshall perspectives is a fellow named Dan Germany [phonetic]. Dan is now with Allied Signal as part of the USA [United Space Alliance] team, but he originally came here as a Marshall resident office guy, having been at Huntsville.

MCDONALD: [Unclear]?

LOFTUS: Yes, and then eventually he [Germany] retired here as the orbiter project manager.

MCDONALD: One of the areas we're particularly interested in finding people is the science research side. Most folks we've seen today has been on engineering activities and all this on engineering marvels, and less on the scientific investigation. A lot of that, I know, [unclear]. Who would you suggest that we talk to, [unclear]? [unclear].

LOFTUS: Well, let's see [for Apollo]. Mike Duke is retired, but he's still here. He's over at the Planetary Institute. Mike was the original custodian, Lunar Curatorial Facility, a Caltech geologist with a lot of insight into that. [Bob Piland would be appropriate.]

One of our big science activities, a trade-off between science and operations, was site selection. A fellow by the name of Jack [John R] Sevier, who's also over at the Institute, was sort of the executive secretary of the Site Selection Panel, because that was a trade-off between places that were geologically interesting and operationally hazardous and how did you balance those considerations.

I was involved fairly extensively, because I headed up the design team that did the redesign of the command [and] service module…[and] the lunar module for the later missions, where we extended the stay time to seventy-two hours and built a lunar rover and more elaborate packages of experiments and what have you, [and] put a lot of other instruments in the open bay in the service module. I had run the team that did all that design.

Obviously, one of the people you'd want to talk to is Harrison [H. “Jack”] Schmitt. He's living out in Albuquerque [New Mexico], consulting. Joe [Joseph P.] Allen is here in the area. It would be worthwhile to talk to him. It was a very macho pilot-oriented kind of culture that developed in the astronaut corps, because these guys were all out of either Pax [Patuxent] River or Edwards as test pilots. So when we first selected the group of scientist-astronauts, they were known as the XS-Eleven. [Laughter] They had a diverse set of experiences. They were all good scientists. Some of them developed into pretty good pilots. Joe certainly is one in that category. Others had difficulty with the flying. But there's one perspective that you can get from that group.

MCDONALD: Life sciences-type people.

LOFTUS: We didn't do a whole lot of life sciences until we got into the [Skylab and] shuttle era. Largely because flights were short, we didn't have a lot of opportunity to do that. So mostly what we were doing through Apollo was essentially geology.

We have, each spring here, a Lunar and Planetary Science Conference. It runs for about four days, and it is the largest gathering of people in planetary science that ever happens. We've been doing that since the first one twenty-seven years ago. Practically all of the people who had a role in that activity attend that conference, because it's a very large exchange. I'd have to sit down and dig out a few names, but the guy who could probably rattle them all off is Mike Duke, [Jim] Head…[at] Brown University, is still active.

Shoemaker was the most active, but unfortunately he's passed away. The reason I think Gene would have been particularly interesting to talk to is that we started using him as a science source in Mercury, in terms of briefing the crew as to how to recognize various geological kind of phenomena from orbit and what have you. So he's the only one I know who was alive at the time who had that kind of continuity through the program. Most of the others came in during the Apollo era.

The reason we didn't do much life sciences is that you couldn't do wet chemistry or that kind of laboratory activity until you got to Skylab. So Skylab was really where we started significant life science. We had done very small things with frog eggs and that kind of thing earlier, but Skylab was the first time we had a real laboratory. So while the primary instrument for Skylab was a solar telescope, because we had the large crew quarters and because we had eighty-day kind of cycles and what have you, we did a fair amount of life science. There are some fairly good reports on--so the best way to deal with that would be simply to go start combing through the list of authors.

Gerry [Gerald R.] Taylor is retired, living up in Colorado, but Judy Robinson here has him on a consulting role. He'd certainly be worth talking to. Howard Schneider is retired. He's living out in Arizona, but he comes in periodically because we have him on contract as a consultant. Jerry [L.] Homick, who is the deputy of our Medical Sciences Division, was one of the major investigators on Skylab and had been one of the major investigators in our earliest terrestrial programs to try and understand the space adaptation syndrome. We have this phenomena that about a third of our people accommodate pretty readily to weightlessness, about a third get nauseous and malaise, and a third get violently ill. [Laughter] Jerry worked in that area. He's very good. Millard [F.] Reschke, who's in his organization, is another one who worked in that area. There was sort of a human factors task and work performance group. Joe Kubis is dead, Ed McLaughlin [phonetic] is dead, and I don't know where any of the others—there were six authors on that. I don't know whether any of the others are still around or active.

Owen [K.] Garriott was a scientist-astronaut, and he is now, I believe, with Teledyne Brown in Huntsville, and would be a worthwhile guy to talk to. John Rummel, who is our acting director, was one of the physiologists who was an investigator on Skylab. Joe [Joseph P.] Kerwin, who is now the president of Wylie life sciences here, was also a scientist-astronaut. He was a test pilot physician in the Navy who came with us and did his thing as an astronaut, and then he was the director of life sciences for a number of years. Then he left ten years ago, or eleven years ago, and went to Lockheed, and Krug hired him away from Lockheed last year. [Krug was acquired by Wylie in October 1997.]

Arnold Nicogosian, who is now the associate administrator for life science and microgravity, was a primary flight surgeon on Skylab. [John Rummel, Deputy Director SISD was a Skylab P.I.] Larry Dietlein [phonetic], who is the assistant director here, was a guy from the Public Health Service who was detailed to us. He retired there and came to work directly for NASA, but Larry has run, practically from the beginning, our Institutional Review Board. Following World War II and the Nuremberg Convention, international and national law requires that you have an Institutional Review Board who reviews any activity which involves human subjects, to be sure that it is ethical and has scientific merit and all of those kinds of things. Larry has been running our Institutional Review Board since time immemorial. So that would get you some of the life sciences stuff.

A good person to talk to about some of the microgravity stuff would be Bonnie Dunbar. That was her training. That's how she got her doctorate, was working on microgravity phenomena. And then there are a couple of guys over in our Medical Sciences Division: Dennis Morrison and Neil [R.] Pellis have done interesting work in that area.

MCDONALD: I know that you know these guys and I don't. What about the institutional side of the house, you know, just working, putting this place together and developing the physical plant and the systems?

LOFTUS: Bob Piland's brother Joe, his older brother. I don't know where Joe is, but our personnel people would be able to help you.

MCDONALD: Well, we're talking to Bob Piland.

LOFTUS: Essentially, when we moved down here, we were scattered all over southeast Houston in various office buildings. Some of us were in what is now Oshman's warehouse at the corner of I-45 and OST. The office complex just to the south of that was occupied. The Lane Wells Building and buildings all over. If you know where there's a K-Mart and a shopping center on the west side of the freeway and the bayou, Simms Bayou there, that whole complex of apartments on the south side of Simms Bayou was all occupied by what is now MOD. We took up every habitable building at Ellington, and we had a pretty liberal definition of "habitable," because some of them didn't have wall-to-wall floors. [Laughter]

In effect, the [U.S. Army] Corps of Engineers built this place for us, but we had a lot of voice in how to lay out the campus, design the buildings, and see to it that there were enough conference rooms and all these kinds of things. So we didn't get a conventional government campus. And I think the guys who did it did a superb job. It's held up pretty well.

MCDONALD: It must be thirty some-odd years old and its in shape.

LOFTUS: Yes. Unfortunately we're not putting as much into maintenance as we should.

MCDONALD: If we get all these guys interviewed in the next year and a half, I'll be happy. You know you're on our list—you know that, don't you—to be interviewed? That wasn't the purpose of this meeting, but I do have a couple of questions. What is that on there, that rocket?

LOFTUS: That was one of a number of configurations we looked at for building a heavy lift vehicle out of shuttle derived hardware.

MCDONALD: This is shuttle derived hardware—these aren't F-1s. These are SSMEs [Space Shuttle Main Engines]?

LOFTUS: J-2s. They were just cartoons, if you will.

MCDONALD: [Unclear]?

LOFTUS: It was a fairly serious study, but just not exactly the—

MCDONALD: I’m always interested in talking about shuttle replacements. I think Jay Honeycutt puts it well. He says the Shuttle's the DC-3 of the human space flight. It'll be flying forever and ever, basically, until somebody wants something orders of magnitude better.

LOFTUS: Well, the rocket equation is extraordinarily straightforward, and you really, really have to change materials technology if you're going to do anything significantly different. I don't think there's anything wrong in trying to design a single stage to orbit, but God didn't mean launch vehicles to be single stage.

MCDONALD: The physics don't help to support it. What do you think about a fly-back booster? I was just wondering, because you've been around so long.

LOFTUS: Well, fly-back boosters are difficult for the same reason single stage to orbit is difficult. Basically, until we can really get to advanced materials, engineered materials, basically things like polyumate and carbon kinds of composites, you can't really do much. There are two essential problems, and that is, you want to go with hydrogen and oxygen for specific impulse, but metals become brittle in continued exposure to hydrogen [and mechanically stressed by thermal chancges]. So you've got a real problem.

One of the problems with hydrogen and oxygen is when you imbed the tankage inside the airfoil, you've now got the problem of having to build all your electrical harnesses and everything to stand the condensation environment that that cold tank creates. That means your wire harness now begins to look like an underseas cable. So it goes up in weight and complexity and all of these kinds of things. So the key to anything like that is going to have to lie in truly advanced materials, and while we've made a lot of progress in the last twenty years, it's not obvious to me that we're there.

MCDONALD: Thank you very much for your time. [End of Interview]

ORAL HISTORY 2 TRANSCRIPT

JOSEPH P. LOFTUS, JR. INTERVIEWED BY SUMMER CHICK BERGEN

HOUSTON, TEXAS – 27 OCTOBER 2000

BERGEN: Today is October 27, 2000. This oral history with Joe Loftus is being conducted for the Johnson Space Center Oral History Project at the offices of the Signal Corporation in Houston, Texas. The interviewer is Summer Chick Bergen, assisted by Carol Butler.

We're so glad you could be with us today, Mr. Loftus.

LOFTUS: You're welcome.

BERGEN: Why don't we start by giving us some background. I'd like to hear about what you did in the Air Force, but even before that, I was wondering how you—what led you to study psychology, that you got your bachelor's and master's degree in.

LOFTUS: Well, I grew up in Washington, D.C., a small suburb of town called Greenbelt [Maryland], and went to Jesuit High School in Washington, D.C., Gonzaga. When I left there, I went in the seminary for three years. There had been several members of my father's family and my mother's family who had been clergy. But I decided, after three years, that that wasn't for me. So I went to Catholic University [of America] in Washington, D.C., then, to complete my undergraduate work.

At that time the Korean War had a draft on, so in order to avoid the draft, I joined the ROTC [Reserve Officer Training Corps], finished up a bachelor's at Catholic U., and had a fellowship offer at Fordham University [Bronx, New York] and went to Fordham in New York, to pursue graduate work. Since I had only two years of ROTC as an undergraduate, I had to finish the other two years while I was in graduate school.

Then, because I wanted to fly, I had to sort of drop the graduate studies and go on active duty. Went through pilot training at McAllen [Air Force Base] in Texas, and then at Vance Air Force Base up in Enid, Oklahoma. By that time the war was over. When wars end, fighter pilots become a glut on the market, so I was assigned to Dover Air Force Base [Delaware] to be the adjutant in the operations squadron, the squadron that's sort of responsible for all the functions of the base.

I was just going to do that and finish up my Air Force time, but I got a query from the folks at Wright-Patterson Air Force Base [Dayton, Ohio]. They had a number of joint projects between the aeromedical laboratory and the avionics laboratory, so they asked me to come out and chat with them, and I did. They said they'd like to offer me a position, so I said, "That's fine. Let's talk about the position." And in the Air Force, everything is doing by a manning document. So a position is not a vague verbal description; it has an explicit number as well as a description.

So I went back to Dover. Since I was a pilot, I could get a T-33 to fly out to Wright Field and fly back to Dover. So eventually a telex message came in that sort of said, "Would you like to take assignment to Wright Field?"

And I responded that I would accept the position, and I spelled it all out for the manning document. The major who was the personnel officer at McGuire [Fort Dix, New Jersey], which was our headquarters, said, "You can't do that. That's only done for general officers." I said, "Well, your suspense date is tomorrow and I'm not going to change." So the thing went through and I got orders, so I went to Wright Field and went into the personnel office to check in, and the fellow that greeted me said, "Am I glad to see you. You're my replacement." And I said, "No, I'm not. Read the orders."

So that was a useful defensive move, and I did get, in fact, the assignment that I had wanted. Basically I was assigned to a group in human factors in the aeromed lab, but I did most of my time working with the avionics laboratory. The reason is that the kind of psychology I studied is probably not what you would envision. Basically what I was doing is looking at kinesthesis. How do you know where your arm is when it's behind your back? How do you know when a car is handling properly?

So most of the work I was doing involved things like applying servo theory from electrical engineering to the way people function at their interface with machines. That was of some considerable interest to people in the avionics lab, because at that time we were still having a lot of trouble with the control systems on jet aircraft.

So I started doing that kind of work at Wright Field, participated in a lot of the test flights that we were doing for developing Category Three landing procedures, which is landing with only 100 feet of elevation for clouds and 100 feet of visibility on the runway, severe weather kind of landing conditions. And we were doing some studies of how would you control spacecraft, or could people control launch vehicles, and things of that variety. Because of that, I got involved on the X-15. The X-15 was typical of the X aircraft of that era, that they were joint projects of the NACA [National Advisory Committee for Aeronautics] , the Navy, and the Air Force, and so through that activity I began to get to know quite a few of the people at the NACA, many of whom were later parts of the Space Task Group. So I worked on the Air Force side of trying to get man in space soonest.

Mr. [Dwight D.] Eisenhower decided that he did not want to export the Cold War into space. He wanted a civil space agency. So he, in effect, gave the assignment to the NACA, which became NASA, and that was a fairly big jolt for them, because it meant they had to have a whole host of new skills and large numbers. So through those interfaces, Charlie [Charles J.] Donlan, who was the Deputy Director for Space Task Group, said he'd like to have me, and that went up through Mr. [Hugh L.] Dryden and across to the Air Force, and in due course I got orders assigning me to Space Task Group.

But I did not want to move my family at the time. We had a couple of new children, and I had a nephew that I was raising. It was not a good time to move the family. So I worked out an arrangement that I would commute from Wright Field until such time as a new home for the Space Task Group, which eventually became the Johnson Space Center [Houston, Texas], was designated.

So I'd pick up an airplane Monday morning and go to work, might be at Kennedy [Space Center, Florida], it might be at Langley [Research Center, Hampton, Virginia], it might be at the Draper Lab [Massachusetts Institute of Technology] in Boston or Cambridge, Massachusetts, or it might be at what was then the Lewis Research Center or Glen [Research Center, Cleveland, Ohio], or it might be at McDonnell [Aircraft Corporation] at St. Louis [Missouri], or two or three of those places in the course of a week. So I did a lot of traveling, but it was very exhilarating.

Then when the site was selected here in Houston, at first we were just renting buildings all over the southeast part of Houston, and my first office when I moved down here was what is now Oshman's warehouse at the corner of I-45 and OST [Old Spanish Trail]. So it was a hectic time, but it was fun.

BERGEN: When you first started with the Space Task Group, what were your—what was your original assignment and responsibilities?

LOFTUS: Well, we were a very, very small organization, and I was assigned to what was called the Astronaut and Training Office, and basically worked on such things as the controls and displays and the caution and warning and the development of interface between the crew and the vehicle. We had such things, for example, as how do you decide whether or not to abort. In Mercury we had a launch escape tower which could pull the capsule off of the rocket.

So we spent a lot of time trying to devise the right kind of instrumentation to be able to say that you never abort on a single cue, and preferably what you'd like to have is something that is sensed by an instrument, seconded by something which can be sensed directly by the crewman so that he could confirm that he was not getting an erroneous indication from an instrument. That was a very long and arduous debate, to try and devise the right kind of scheme to do that, but we did it successfully.

BERGEN: Who did you work with to make these decisions?

LOFTUS: Well, there were a whole group of people that would be involved in these kinds of things. Because we were so small, the crew was involved in a great deal of this, and that was not a particularly onerous problem, because I had done a lot of work and flying with Deke [Donald K.] Slayton and [Virgil I.] Gus Grissom when we were at Wright Field.

At Wright Field one of the things I had done was some of the flying in zero-G aircraft, and Slayton on occasion would fly those missions for us. Again, it was partly to understand whether or not in a weightless environment there were significant changes in motor behaviors, but we also did all kinds of other things that were of interest.

One family of experiments I did involved cats, to sort of say to what degree is a cat's reflex for landing on its feet a visual thing and to what degree is it a gravitational thing. So we did experiments with cats that had tails and cats that did not have tails, like the minx cat. My colleagues from those days in the lab have never let me forget that. [Laughter] But it was clearly demonstrated in that family of experiments that it was a visual cue that the cat was using, and cats that had tails could get themselves properly oriented more rapidly than those who did not. So it was an interesting demonstration of the conservation of momentum.

At any rate, this zero-G aircraft was a lot of fun, and we used that then later on for training the crews and eventually we moved the aircraft down here. I guess we're now in the third generation of the aircraft.

I guess one of the other interesting things that I did in the years at Wright Field was a special assignment for General [Bernard A.] Schriever. At that time the economy was good, and when the economy's good and there's no war, it's hard to keep people in the military. So the military was having a great deal of difficulty with that. Over several years there were commissions appointed to advise the Department of Defense [DoD] on what to do and how to do it, to solve this retention problem.

There had been a commission chaired by the chairman of General Motors that had made a report, and when they finished looking at the report, General Schriever said, "It's the lieutenants who don't stay in the Air Force. Why don't we ask the lieutenants." So he recruited a group of sixteen lieutenants. At that time he was the Commander of the Air Research and Development Command, and he was headquartered at Andrews Air Force Base in Washington [D.C]. I was at Wright Field, which was one of his stations, as were other stations such as Electronics Research Center in Cambridge and the laboratories out at Kirtland, New Mexico, and Eglin Air Force Base [Florida] and so on. So in order to have proportional representation, he took one lieutenant from the smallest installations and then proportionally more lieutenants from the larger installations, so that's how, with twelve installations, we wound up with sixteen lieutenants.

His Deputy Chief for Personnel was General Dougherty [phonetic]. So the first day we met, we sat down in the conference room with General Schriever and he explained to us what his concern was, why did people not find the Air Force an attractive career, what could be done about it, and then he told General Dougherty, "Give them anything they want."

So we were then left to ourselves and tried to get ourselves organized. We basically decided that we would look at the problem and several working groups, one on compensation and one on career progression and things of that variety. Then we met with General Dougherty and said, "We don't really understand very much about compensation systems. Have you got somebody who can help us?" And we went through half a dozen subjects on which we needed things. So the following morning he met with us and said, "Okay, we're going to start by giving you guys a series of briefings." So they had some colonels come over from the Pentagon to give us briefings on the future of the Air Force, what was then, and still is, called Air Force doctrine. They had others come over and give us briefings on how was the Air Force budget structured, how was the Air Force as a whole structured, what was going on in research and development. The way they got us people on compensation was General Dougherty ordered to active duty the vice president for personnel of TransWorld Airlines [TWA] and a vice president of General Electric, and a number of other organizations, so they came and did their reserve tour of duty educating this young group of lieutenants on compensation schemes and how were career progressions managed in General Electric and things of this variety.

So it was an interesting experience to have that kind of talent at your command. We decided that we had to do something to sort of quantify a lot of the observations, so we did what we called twin studies. How did two brothers, twin brothers, one going in the Air Force and making a career of the Air Force, and one going into the Air Force, then leaving to go into some other line of work or, in another case, never going in the service, but progressing in his own profession, and that had some revealing insights, because the general belief was that the primary competitor to the uniformed services was the industry.

Turned out the primary competitor was the civil service. So that was an interesting thing, to sit down and, in effect, do a lifetime income stream for somebody in the military. We did an average Joe, above average, below average case, compared them all. It was very instinctive. So we wound up concluding that pay was part of the issue, but the largest part of the issue was that people didn't like the job assignments because mostly what would happen is that people would come out of engineering school and they'd want to go do engineering, but they'd be assigned to some project office where what they'd be working on was configuration control paper and change orders that were going out to contractors to do various modifications to equipment. So they weren't getting any real hands-on engineering experience.

The other thing was, the Air Force, because, like all military organizations at that time and still to some degree at this time, sort of believed that it had to train its professionals so that in the event of a war you could expand the numbers very rapidly, so your core, you wanted to have a broad knowledge of everything that the service did. So that meant they'd give you a new assignment every three years or so. Well, that's disruptive to families and for people who believe they were learning an engineering profession. It was disruptive to developing the kind of skills.

So one of the recommendations was that for your first assignment you ought to be doing hands-on engineering and you ought to do it for at least four or five years before you get another assignment, so that you can take the skills that you learned in school and really develop.

So we went off and prepared a report, and at that time you did all your briefing with flip charts on an easel, and that meant that any organization like General Schriever's had an office which could do very fine lettering and graphics of all sorts for this kind of thing, so we prepared a briefing and it had seventy-nine flip charts. We were told by Schriever's aide that he just didn't have time to sit through that kind of thing. And we said we didn't know what to take out.

So we went in and we were scheduled for two hours, and the meeting lasted about four hours, but General Schriever listened to it all and he said, "Well, this is what I was looking for, is what really is it that we have to do to fix the system." And he turned to General Dougherty and he said, "I want you to take this across the river to General Ferguson [phonetic]," who was the DCS [Deputy Chief of Staff] for Personnel for the entire Air Force.

So the following day, we went across the river—the Pentagon is across the river from Andrews—and briefed General Ferguson, and General Ferguson said, "This is very good. I want the old man to hear it." The old man was Curtis [E.] LeMay.

A word on Ferguson. He was sort of an interesting fellow. When NASA was created, he went over to see Dr. Dryden, who was the [NASA Deputy] Administrator, and he said, "I've got 600 engineering graduates this year with ROTC obligations. Any of them that you want to take, I'll relieve them of their service obligations." That was a tremendous infusion of youngsters into NASA that was sort of a class act by Ferguson.

So at any rate, they decided they couldn't take all sixteen of us to see LeMay because it was going to be done in his office, so they took six of us. We went in to see LeMay and set up our easel, went through all the charts. He sat there, never made a word, never cracked a grin or anything, just sat there and puffed on his big cigar. When I finished the briefing, he said, "That's interesting." And he stood up and he walked over to the easel and he flipped all the charts back to the beginning and then he went through them, making comments. Very interesting. Again, it was one of these things, we'd been on his calendar for like an hour, an hour and a half, and four hours later we marched out of his office and in the anteroom, in the corridor outside were full of all these flag-rank officers who were looking at all these young lieutenants, sort of saying, "What's going on?" So that was a rather interesting experience to get exposed to those kind of people at that point in my career.

So at any rate, that was sort of the background as to how I got to NASA. We worked very closely with the McDonnell folks, because we were a small team and because at that time the community was small. I knew a lot of the NACA people from X-15 times, knew a lot of the McDonnell people from other contacts, so it was very much sort of a team kind of an arrangement.

One of the fellows I worked very closely with at Langley was Al [Alan B.] Kehlet, who was an aerodynamicist who was very involved in this business of trying to figure out how do you do abort criteria and so forth. Another was Dick [Richard R.] Carley, who was involved in a lot of the simulations of the control systems and so forth.

And it was interesting to work with John [F.] Yardley, who was the McDonnell program manager and one of the most impressive individuals I've ever known. When people would be making presentations or talking in meetings about some system or part or what have you, he would say, "Do you mean this?" and he'd give you the drawing number. He had the entire drawing tree committed to memory. Absolutely phenomenal mind. And there were other people that were a big part of the operation—Chuck [Charles W.] Mathews, Chris [Christopher C.] Kraft [Jr.] , Sig [Sigurd A.] Sjoberg. I'm sure you've talked to a lot of these people or heard lots of anecdotes about them.

There was an interesting culture in the NACA, and it was not unlike some of the things in the Air Force, and that is, since the primary product of the NACA was research findings, they had very demanding standards as to how you would put presentations together, what type sizes to use on slides, and how many words could you use on a slide, all of those kinds of things, and they were very demanding in the way they wrote their technical reports in the interest of clarity. So it was an interesting culture in which to work.

They also, like the DoD, had a real premium on being able to make a good presentation. People who made good presentations did well, because it was believed that if you could make a good presentation, it was because you really understood what you were talking about. So it was a way of testing people's knowledge of substance, and it worked. We had lots of interesting things happen. It was interesting to be preparing for a test launch before we were going to fly people, and have the launch escape tower take off all by itself. That put a little of the fear of God in you. [Laughter]

[Alan B.] Shepard's flight was quite exciting. We obviously regretted that Mr. [Yuri] Gagarin had gotten ahead of him, but we were very pleased with the results of Shepard's flight. Then, of course, we had the problem on Gus' [Grissom’s] flight that we lost the hatch and we nearly lost Gus. The reason we nearly lost Gus is that for some reason he had not put up the neck dam in his suit. In the suit, inside the hard cover, we had a rolled-up rubber neck dam, and the notion was that when you're in the suit with the helmet on, you wanted the atmosphere to move freely back and forth between the body area and the helmet.

But when you took the helmet off, particularly if you were in the water, we didn't want to get water in the suit because you couldn't support it. Well, the neck dam was supposed to take care of that, but Gus had not unrolled the neck dam, so when he took off his helmet and the hatch blew, he was taking water into the suit at a great rate. Turns out the helicopter pilot who pulled him out was Dr. Jim [James L.] Lewis, who worked here for many, many years, and just retired recently. So that was a pretty close call.

And I tell you that little story because the next flight, of course, was John [H.] Glenn [Jr.], and after the flight, a number of us were sitting in a conference room, looking at the camera films, and one of the fellows said, "Look. John doesn't have his neck dam up." And about five minutes later, John walked in, and we told him, and he didn't believe us. So we backed the film up and showed him. He just shook his head and walked out of the room. But it's the kind of thing that can happen to you in an operational setting.

When I was at Dover, one of the things we had to do was to check out bogies who were in air defense identification zones. These are zones where civilian aircraft were prohibited. As the case with such things, we'd regularly get intruders and then we'd send somebody out to identify them and chase them out. I went on a flight to do that one night, and I had the nagging feeling that something was wrong and I couldn't remember what it was, but we found a twin- engine Cessna, waved him off, got him out of the area, came back and landed. It was when I undid my seatbelt and harness that I recognized that I had failed to fasten the leg straps on my parachute. I think I lost five pounds right then and there. [Laughter] Just pure cold sweat. So that's why you have checklists and why no matter how often you've done it, you need to follow it.

It was about that time that we had selected Houston [for the site of the Manned Spacecraft Center]. Have you heard all the stories about how that came to be?

BERGEN: I think every time we hear one, we learn something different, so we'd love for you to share that with us.

LOFTUS: Well, at that time the land that is the site and much of the land that is Clear Lake city was all land that was owned by Humble Oil Company, the predecessor of Exxon [Mobil Corporation]. There was a developer who was an imaginative fellow, and he went to Humble and said, "You don't really need the surface of the land. All you want is mineral rights and what have you. So why don't we form a corporation to develop that land." And that became Friendswood Development Corporation. And they then took a large chunk of the land and gave it to Rice University, because Rice, as a 501(C)3 corporation, an [unclear] institution, could give things to the government that a profit-making corporation couldn't do. So that was part of the Houston package as a bid for the new Manned Spacecraft Center, was that they gave a piece of land via Rice to the federal government as the site.

The city council did a gambit that Texas has an extraterritorial jurisdiction law that says you can annex an area equal to 10 percent of your land area each year and you can bank that for three years, so you could, in one year, annex 30 percent of your present land area.

At that time Houston was in its third year, and as part of their activity to capture the Manned Spacecraft Center, they annexed a strip of land ten feet wide and drove straight south down south Main Street till the edge of Harris County, and then east along the margins of Harris County until they just had enough left to get back to the eastern side of Houston and, in effect, put a fence around the whole southeastern part of Harris County.

Well, Webster and little places like that couldn't argue with them, but they captured a tract of land Pasadena [Texas] could have captured, that is now Armand Bayou. So Pasadena took them to court because all the little places like Nassau Bay and El Lago and what have you could not incorporate because they were now within the extraterritorial jurisdiction of Houston.

So when Pasadena won the lawsuit, Nassau Bay and El Lago and all these places incorporated the following day, because they were now outside Houston's extraterritorial jurisdiction. The only ones who didn't escape were Clear Lake City, because they still were within reach. So it's been an interesting gambit to watch that kind of thing go on.

Houston was very proud of having won the Manned Spacecraft Center, and they had big doings for us down at the coliseum and the Astrodome. The night they opened the Astrodome was a disaster. They had offered free admission to all Boy Scouts and Cub Scouts and what have you. Of course, most of us had kids who were in the Scouts. I started driving towards the Astrodome, and pretty soon all the radio stations were saying, "Everybody please stop, turn around and go home. We've got gridlock." [Laughter] And literally it took maybe three hours to get untangled and get back home because there was such a horde of people all headed for the Astrodome, because nobody had ever seen it, and it was interesting.

Well, while we were at Langley, after Glenn's flight, a number of us were put to work to go look at how would you go to the Moon. I was part of that group that was looking at how would you go to the Moon. There was a fellow at Langley, John [C.] Houbolt, who was an advocate for lunar orbit rendezvous. I got to know John while we were at Langley. It was an interesting scheme. John's lunar module didn't look at all like the one we wound up building, but that wasn't the point. The point is that he was pursuing the strategy of staging to its logical conclusions. So that was an interesting introduction.

We started laying out something that was very, very similar to the command module we eventually used, and as is always the case, we had advisory committees. I can remember sort of a difficult afternoon with an advisory committee that says, "Why are you selecting a three-man crew? Three is a bad number, because two of them will gang up on one of them, and that's sociologically not a good arrangement."

We said, "Two's not enough and we don't have room for four." [Laughter] It was that kind of thing that sort of made you wonder about the value of advisory committees, but part of it is they made you work and made you think things through and recognized that that was the situation that could develop and that you'd better think about that in the way you trained and organized things.

We began moving down here. I came down just after Christmas in 1961, brought my family down, and we bought a house up in Overbrook, lived there until the site got built down here, then I moved down to Nassau Bay. We were spread out in lots of places around Houston, and, of course, that's where we were when [President John F.] Kennedy came through. He visited a number of our facilities, looked at some of the mockups and things that we were doing. That was my first encounter with the Secret Service contingents and the press. The press have no regard for anything. The photographers are particularly bad. They'll knock things over, including you, to get at the picture.

Then, of course, the following day, he [Kennedy] was assassinated in Dallas, so that was a pretty memorable event.

BERGEN: What do you remember about when he first made the commitment to go to the Moon?

LOFTUS: Well, we knew that it could be done, that it was a question of did you have the right kind of resources. You have to remember that World War II really changed the structure of the world. By the end of the war, we were flying bombing raids at 36—38,000 feet in unpressurized aircraft, which meant that you had to develop breathing systems for crewmen and what have you. So that sort of all of the things that you would need to sustain a human being in space, you had learned to do.

The second thing is, is that the military is a training machine. Amateurs think that wars are won by tactics. Professionals know that wars are won by logistics and training. So one of the things that was done is we trained literally tens of thousands of people to be pilots and tens of thousands of people to be mechanics and tens of thousands of people to do scheduling and route management and what have you. So before World War II, there was essentially an embryonic civil aviation, but out of World War II was this tremendous endowment of equipment and people that literally, within years, two years, created the aircraft industry as we know it.

During the war, there were 12,000 DC-3s built. There's still some of them flying in South America. But that meant that after the war, you could get a group of pilots and a group of mechanics and a group of schedulers, and you could set up an airline. And they did. Dozens of them, most of them gone, now embedded in much, much larger airlines, but there must have been, in 1947, maybe fifty airlines in the United States because of this endowment of equipment and people. So that changed the way transportation was done, both air cargo and air passengers. In effect, that led to the Chicago Convention of 1947, which is the International Civil [Aviation] Organization [ICAO]. It's now part of the United Nations. But that is the forum in which people agree as to what will be the rules of airport operations, flight operations, traffiicmanagement, lighting schemes for airports, what have you, and that's where English became the

language of aviation worldwide. And that's still how it's done.

So literally every nation in the world belongs, because whether they have an airline or not, they want other airlines to service their country, and that means they have to meet specifications about bearing strengths of runways, what are the heights of the passenger exit doors, and all of the accoutrements that interface the terminal to the airplane. So that was an interesting development out of all of that. And it works well. Nobody tells anybody else what to do; everybody gets together and decides what's in the common interest. That's sort of a diversion, but I had gotten into some of that when I was doing the research at Wright Field on the CAT-3 landings and was very interested in all of that.

So at any rate, we knew how to sustain human life. We had learned how to build pressurized cabins so we could build them for spacecraft. Two-thirds of the atmosphere is below you when you're at 30,000 feet. Half of it's below you when you're at 8,000 feet. So going the last 10 percent out of the atmosphere to go into space was not a particularly significant thing in terms of a lot of the design parameters of the vehicle. The biggest issue was going to be how heavy were you going to be and could you build a launch vehicle big enough to do it.

Well, of course, after World War II, the U.S. has succeeded in capturing most of the German V-2 team from Peenemünde and put them out in Fort Bliss out at El Paso [Texas], but then they wanted to build some Army launched vehicles, so they brought them up to Huntsville, Alabama, to the [Redstone] Army Arsenal there. Wernher [von Braun] had the notion of some really big launch vehicles. I'm not sure whether he and [Sergei Pavlovich] Korolev had ever had any contact with each other, but they both had the notion of multi-engines in the first stage. So Wernher said he could deliver a big launch vehicle, and they did a marvelous job.

We kept trying to get the weight down, and that led to a number of significant things. One of the big debates, of course, that prevailed during those years in Apollo were, should you go Earth orbit rendezvous and build a space station and depart from the space station to go to the Moon, or should you go lunar orbit rendezvous and not spend any time in Earth orbit? That was a very profound kind of decision that had to be made, and the fellows at Marshall [Space Flight Center, Huntsville, Alabama] were developing the Saturn, and we were trying to develop the command and service module and lunar module. All of our weight targets were being exceeded, which meant that he had to keep building a bigger and bigger vehicle or he wouldn't be able to lift everything we had. So there were lots of fairly acrimonious discussions and lots of real learning experiences.

BERGEN: Were you involved in any of that decision-making process?

LOFTUS: I was going to tell you a few stories about that.

BERGEN: Great.

LOFTUS: One of the things that happens after there's a big competition is that some company wins the competition and then it has to staff up to actually do the job. So one of the things that happens is people who are working for the losing corporations may go to work for the government agency that's going to supervise the program or they may go to work for the contractor who won the award. And that's where a lot of the NASA people came from. They came from the [Glen L.] Martin Company in Baltimore [Maryland], which had bid for Apollo and lost to North American [Rockwell Corporation], or they had worked for General Dynamics [Corporation] in San Diego, lost to North American, and rather than go to work for North American, they came to work for NASA. So we had lots of that kind of infusion of people. But that was sort of the second major infusion.

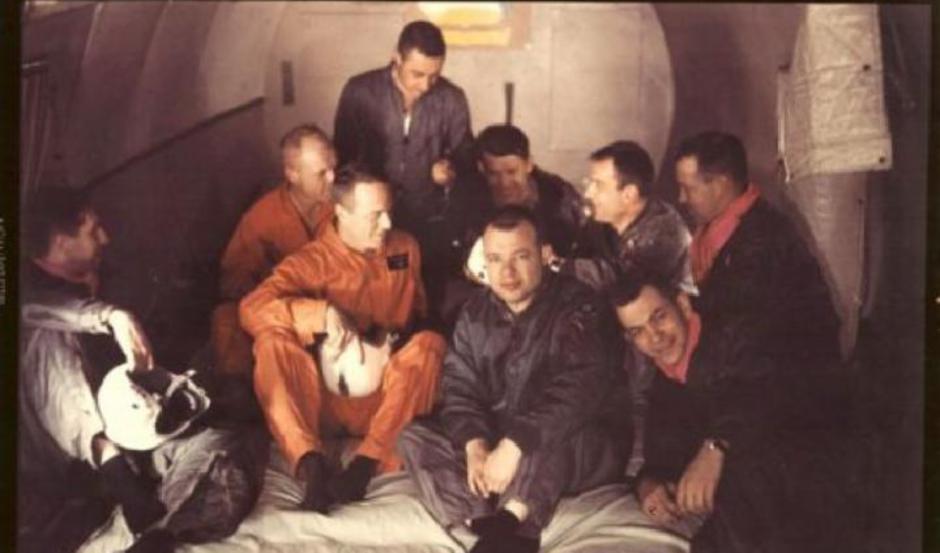

The first major infusion of people for NASA was the Canadians. Shortly after Mercury was started, the Canadian government, under Mr. [Prime Minister John] Diefenbaker, decided that they were too small a nation to compete in building front-line fighter aircraft. At that time they had a company by the name of AVRO, which is a truncation of A.V. Roe [Ltd.], who was one of the early developers of aircraft. They had an aircraft called the [CF-]105, which was undoubtedly at that time the hottest fighter in the world. They had, I think, five airframes, and they had just started their testing when the government said, "No more. Cut them up. Get rid of them. We're out of the business."

So we promptly went up to Canada and hired as many of them as we could, and McDonnell hired a group. So there was a big infusion of Canadians into both NASA and McDonnell and Rockwell. That was sort of an interesting thing because it had some echoes of the development of the jet engine, because Frank Whipple was a young Brit who wanted to develop a jet engine, but the establishment really didn't think there was much in his proposal, so they didn't want to give him any of the good young British engineers, so they gave him a group of these young colonials from Canada. Of course, Whipple was successful in developing the jet engine.

Part of the consequence of that is that those young Canadians went back to Canada and established the Orenda Engine Company with what they had learned. So they became a fairly significant player in the jet engine business.

So in the space business it was much the same way. We got this young bunch of colonials. Of course, many of them became U.S. citizens, though many did not. But they were an interesting group.

Then, of course, when the contractors lost the Apollo bids, again the winners picked up a lot of those folks and so did we. So there's a lot of that kind of cross-fertilization within the community because of the nature of the business.

We started out on the lunar module, and everybody started out with what looked like a sphere, because everybody knows that that's the most efficient shape for containing volume with minimum weight. I can remember numerous sessions where we'd be trying to figure out how we were going to build this sphere and at the same time have fields of view that we would need to do the landing, need to be able to see down, so you'd have to have windows on the bottom. You'd have to dock, you've have to have windows in the top. Pretty soon the whole front half of the thing was windows and window frames.

It was just getting more and more complicated, and so we kept modifying the design. I think before we were finished, we had done something like nineteen different configuration designs. What's impressive about that is that if you go over to Space Center Houston and look at the ascent stage of the lunar module and you've learned how to look at it, you will recognize that it's a replication of the human skull, that it's got two triangular windows and an eyebrow, it's got a nose, it's got a mouth, it's got a hatch in the top. Turned out that all the same considerations that make the skull the way it is were the right way to make a minimum weight, smallest possible window, symmetrically balanced vehicle. So the crew's in front, the equipment's in back, the fuel tanks are on the side so that everything is balanced. Very efficient design structurally and thermally. Small as possible windows so you don't have a big heat load. It took us a long time to get there when the answer had been sitting across the table from us from the beginning. So that was a real learning experience for a lot of us.

We got into all kinds of things. I had a lot of responsibility for the controls and displays in both vehicles, and had a group in the program office that did that. I can remember very carefully writing the language that said, "You shall not design any instrument so that it fails in place." If you have a needle and the needle is supposed to indicate something if the instrument fails, you fail it off-scale so it's out of sight, so that the crewman knows he doesn't have it. We had worked very hard to get all of that language into the specifications.

I can remember discovering, about two years after we started to build the lunar module, that Grumman's instruments all failed in place. I went ballistic. But it was too late to do anything about it, so we had to try and find ways to deal with that.

The evolution of the lunar module is, I think, one of the most interesting stories. I can remember being in Cambridge for some meetings with the Draper Lab people, listening to a radio show in the morning while I was getting dressed and ready. One of the critics was saying that it was demonstrable that NASA really didn't know what they were doing and we really couldn't afford to go to the Moon because they couldn't even afford to provide seats for the crewmen who were going to land on the Moon. [Laughter] So it's interesting, the kinds of perceptions that you have to deal with.

Probably the two biggest system-wide decisions that had to be taken into the program, at least from the prospective that I was involved in, were who is going to be primary for navigation. Were you going to rely on onboard navigation, and would that be primary? Or were you going to rely on ground navigation, and would that be primary and the onboard system would be a backup?

A group of people up at MIT Draper Lab, [J. Halcombe] Hal Laning and Dick [Richard H.] Battin, had developed a scheme for doing onboard navigation, and we had done a lot of work with the Draper Lab people, so we tended to be in favor of an onboard solution. But there was another group of people who felt that with proper Doppler ranging in the S-band signals, that they could do the navigation from the ground and do it more precisely. They felt that by not having to do that on board, you could substantially offload the crew from work that was involved in that task that could be better done, so that you could distribute the workload between the ground and the flight crew more efficiently.

That was a major exercise for several years before we finally resolved that we would make the ground primary and onboard secondary, but we kept working on the onboard system so that if for any reason we lost communication, we could do everything on board. That was an interesting development.

At that time, computing power was very limited, and that was one of the arguments that helped the advocates for a ground-based system prevail, because it didn't matter how big the computer on the ground had to be, you could make it. In those days, the computers on board were small and you had to do all the programming in machine language, which was very cumbersome to do, very cumbersome to check out, and even more cumbersome to change. But the onboard computers that we had had less power than your hand calculators do today. So it was an interesting exercise to develop those controls and displays and the sextants. I spent an awful lot of time working on that with the Draper Lab people, and we had a very good system.

We also had some fairly well-trained crews. On one of the flights, Jim [James A.] Lovell [Jr.] was the navigator, and there was an error in procedure, and he dumped the whole computer, and he had to rebuild it in real time in order to get on with the mission, and he did. That's how well trained he was, very successfully. So that was a big decision.

Another one of the big decisions was, what kind of engines were you going to use in the service module to go to the Moon. We had a whole team of people working on that, but in the end, the fellow who presented the case and won the day was a fellow by the name of Larry [Lawrence G.] Williams, passed away a couple of years ago now. Larry was interesting because he and Caldwell [C.] Johnson were two of the NACA people who came into the program, neither of whom had an engineering degree or a college degree. They had both come through the apprentice program at Langley, and yet they were two of the best engineers we had.

So Larry, in effect, put together the story that said what you want is a pressure-fed engine and a single engine, because that's the most reliable system we can build. That, in effect, dictated the kind of service module we were going to have. It was a major decision, and every virtue that Larry had claimed for it was proven true. Very reliable and it worked very, very well.

So that meant that when we built the service module, it was, in a sense, a cylindrical structure and it was in six segments. Four of the six segments were occupied by propellant tanks, two fuel tanks and two oxidizer tanks, and that left us then with two open bays in which we could put other equipment. And amongst the equipment we put in those bays were the fuel cells and cryogen tanks to produce the electricity.

The Apollo fuel cells were sort of third generation baking cells. Second generation is what we flew in Gemini, and the first generation were just laboratory units. Basically a fuel cell is a membrane which acts as a catalyst so that you put in hydrogen and oxygen, and as they react with the catalyst, you produce electricity and water. They worked very, very well for us.

But, of course, on Apollo 13 we did have the accident, and that's another one of those cases where people and procedural errors caused the problem. We had done what we call a Countdown Demonstration Test where we had gone through all the procedures of loading all the consumables such as the cryogens and propellants and everything, as a dress rehearsal for the mission. Then, of course, when we finished that, we had to de-tank everything in order to get back to an empty configuration, if you will. In order to do that, we had to heat the cryogens to remove them from the tank. The technician left the heater on after all the cryogens were gone, and so the tank kept getting hotter and hotter until eventually somebody did turn off the heater. But by that time all the insulation had been charred and fallen off. So then when we tanked for the mission, everything was all right because the wires were separated.

And it wasn't until we were in flight and had to do what we called stirring, because the problem is, is with the cryogen, is that it separates into phases and it stratifies, and you don't want to do that, so we had a fan that you could use to stir up the cryogens. And it was when the fan turned on to stir up the cryogens that it created enough motion to bring those wires together and create a spark. At 900 pounds per square inch in pure oxygen, stainless steel burns like a candle, and that's what caused the problem.

Interestingly enough, as part of the training we had done, we had done a simulation, we hadn't postulated why, we just sort of said, "You've got to get home. You've got no power. How are you going to do it?" And we had actually run the simulation of going around the Moon and navigating back to the Earth and what have you. What we hadn't done in the simulation is we hadn't had to deal with the consequences of no power, but we had in the simulation used the lunar module as a lifeboat. We had not anticipated how cold it was going to get. But because of that, we were able to, I think, pull off something close to a miracle.

Turns out I was not here at the time. I had gone off to a school. I was in the program office, and the fuel cells and cryogens were one of my responsibilities. But we had a large General Electric group working for us, and General Electric, as a company, is very, very big on training. Up at Crotonville [phonetic], New York, they have, in effect, a university campus of their own, where they run people through all kinds of training courses. You can literally get a doctorate in engineering or business or many other subjects in that kind of environment.

But in addition to that, the office of the chief engineer ran a special course twice a year up at Saratoga Springs, New York, and the notion of the course was that they would bring in the

chief engineers from various facilities throughout the G.E. system and they would bring in one or two customers along with these chief engineers. So they took over the Gideon Putnam, a resort hotel, for the six weeks before the season opened and the six weeks after the season, and would bring in their people, about thirty-five or forty.

During this six weeks, they would bring in people who were truly experts, and the notion was that here you had a group of engineers who'd been out of school twenty, twenty-five years, who were the senior engineers for various facilities or functions, and what you wanted to do was to bring them up to date. You wanted to get them trained in the same way that this year's graduates are being trained so that they would know how to make use of those skills. It was very intense. They sent you programmed instruction texts to read before you got there, and they sent you a basic manual so you could produce programming in BASIC. Then you assembled.

I was one of the guests. The other fellow was from the Navy, a Navy commander from the Polaris Program. So you'd go to class six days a week, and the regimen was, class started at 8:30 every morning and went until about 3:00 in the afternoon, and then you took a couple of hours for exercise and PT [physical training], supper, and then after supper, special lectures. Essentially, a lot of the special lectures were a fellow who was an expert in making computer chips would give a two-hour course on how did he do what he do. So everybody taught at least one evening to the rest of the class.

It was while I was at that course that the Apollo 13 event took place, and so one of the things I did every evening was to give a status report, because we were obviously very interesting. I was talking to our people back here to find out what was going on. I did not sleep very well that week.

But that was truly very educational. Just as an example, one of the courses was polymer chemistry. How do you make nylon, [unclear], things of that variety. The fellow who taught the course was Hans Mark, not the Hans Mark who was with NASA, his father. [Laughter] Who was at Brooklyn Poly [Polytechnic University of New York] and who was a marvelous teacher. And the guy who taught metals was the chief metallurgist for U.S. Steel [Group]. The fellow who taught math was the chairman of the math department at Cal-Berkeley [University of California at Berkley]. In forty hours with him, we went through set theory through tensor analysis, which is like four years' worth of math. [Laughter] But he was really good. You know, most of us, a lot of it was review, but it was quite a challenge.

Had a course called transport theory, which really is essentially all forms of conversions of energy, and that was taught by a fellow by the name of Rasmussan [phonetic], who was the dean of engineering at Rensselaer [Polytechnic Institute (RPI)]. That, of course, was the time when campuses were having a lot of trouble. This fellow had played tackle in college, and they were in the midst of a student riot when he was getting ready to come teach us, and he went through them just like he went through the other line. He just knocked people end over end. [Laughter] Big bull of a man.

One of the courses was decision theory, so they brought Ron Howard in from UCLA to teach that. It was an interesting experience to get exposed to all of these academic stars in this very intense kind of environment.

Of course, at that time computers were not as prolific as they are now, but there was a terminal assigned, an old TTY terminal, as a matter of fact, to every student, and you had to do your homework on the terminal. So that was a fairly useful experience.